About Us

Established in 2024 by Mr. Nelvin Varghese, Mr. Dilip Sirsikar, and Dr. Amit P Palwe, Arypal Autoparts has quickly positioned itself as a leader in the automotive OEM’s.

ConsultationContact Info

- Plot no C39, MIDC Chakan, Taluka Khed, District Pune 410501

- +91 93702 22424

- info@arypalautoparts.com

- Week Days: 09.00 to 18.00 Sunday: Closed

Products

- Home

- Products

Our Products

Arypal Autoparts provides an extensive selection of cylinder head components suitable

for all internal combustion engines, including petrol, diesel, CNG, and hydrogen. Our

products are crafted using advanced rolling and pressing heat treatment processes,

ensuring durability, reliability, and superior performance. We are committed to delivering

high-quality components that meet the rigorous demands of modern engines. Trust

Arypal Autoparts for innovative solutions that drive excellence in engine performanc

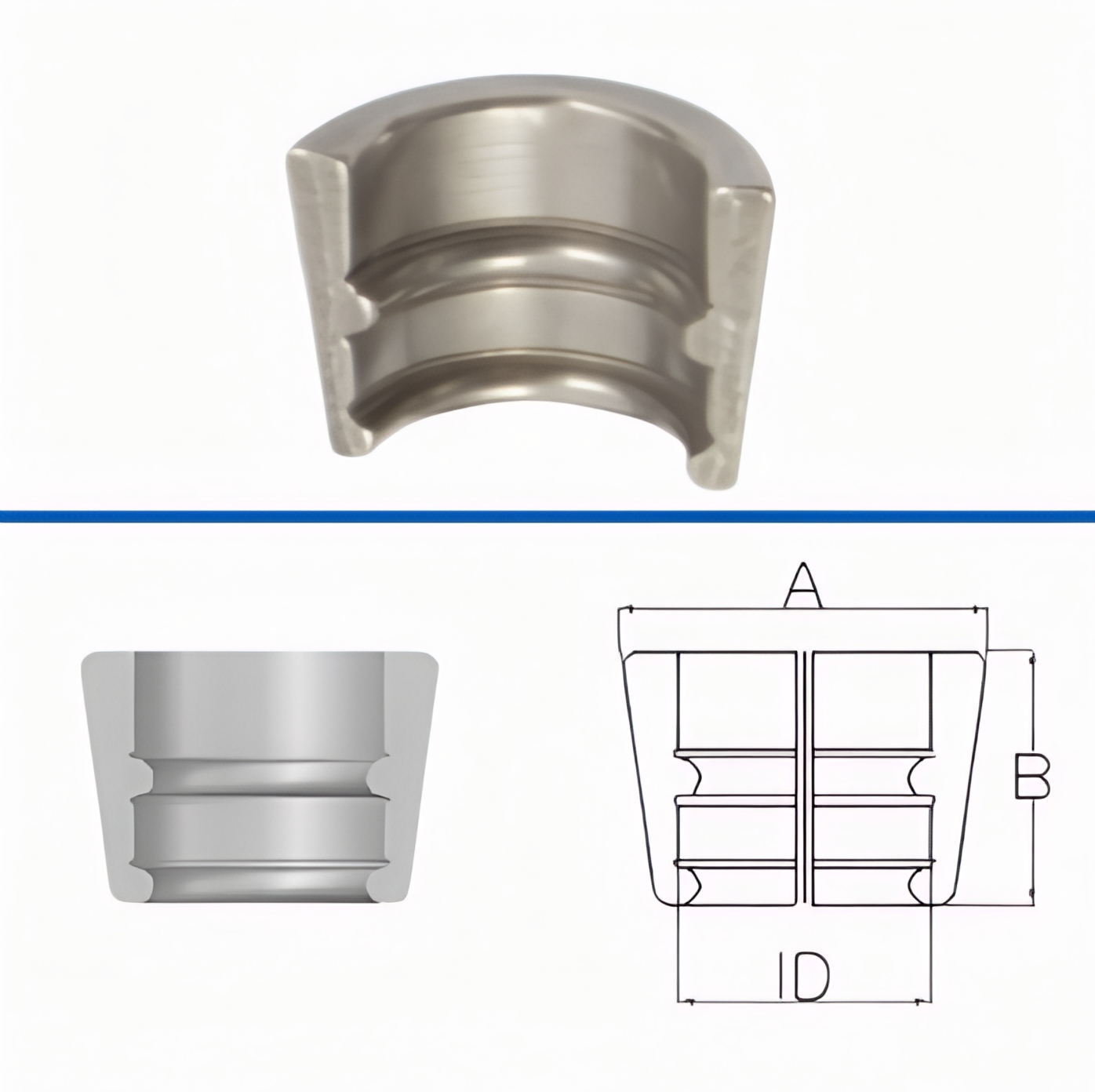

VALVE COLLET/KEEPER

Our valve collets are precision-engineered to ensure secure and efficient valve operation and rotation. We are one of the fewer than three brands that manufacture valve keepers with specialized processes such as rolling, pressing, and heat treatment. Made from high-strength materials, our valve collets are designed to withstand extreme conditions and provide long-lasting performance. These components are critical in maintaining the integrity of the valve system, ensuring optimal engine performance. Our range covers applications from two-wheelers to marine engines.

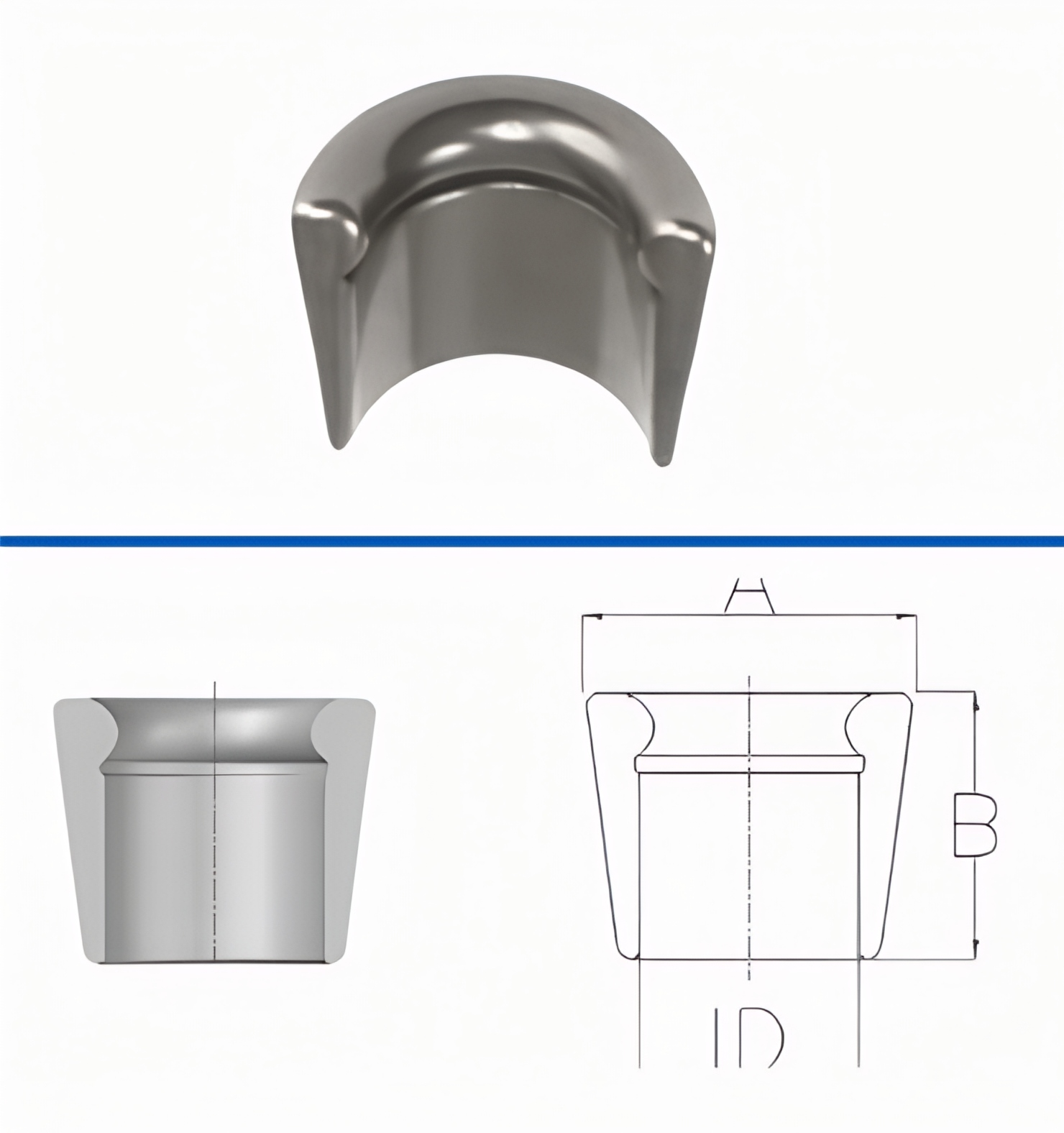

VALVE RETAINER

Our valve retainers are crafted from robust materials to ensure durability and reliability. They play a crucial role in maintaining the integrity of the valve system, ensuring optimal engine performance. We use cold forging machine presses to achieve the right grain flow for better fatigue strength, followed by in-house continuous heat treatment. Our retainers are designed to resist wear and deformation, providing a secure fit for the valve springs. We offer a range of retainers suitable for applications from two-wheelers to stationary engines.

VALVE TAPPET

Our valve tappets are designed for smooth operation and minimal wear. They are a critical component for reducing stationary engine noise and ensuring proper engine settings. We manufacture both mechanical and hydraulic tappets at our state-of-the-art manufacturing facility. Utilizing a special process of rolling and pressing, along with our in-house continuous heat treatment process for hardening, we ensure superior quality. Our fully automated plant features AI-based vision inspection through camera systems and EDDY current sorters.

VALVE TAPPET SHIMS

We offer a variety of valve tappet shims in different thicknesses, allowing for precise adjustments to ensure optimal valve clearance and performance. Our shims are made from high-quality materials to provide consistent performance, high pressure resistance, and wear resistance. They feature an ergonomic design for operator efficiency and safety

PUSH RODS/PUSH TUBES

Our push rods and push tubes are engineered for strength and durability. They are designed to provide reliable performance in a variety of engine applications, from light vehicles to heavy-duty trucks. Our push rods are manufactured to withstand high pressures and temperatures, ensuring long-lasting wear resist performance.

VALVE TAPPET SCREWS

Our valve tappet screws are essential for securing valve tappets in place. Made from high-quality materials, they ensure a secure and reliable assembly. Our screws are designed to resist loosening and provide a strong, secure connection. We offer a wide range of screws suitable for two-wheelers, three-wheelers, truck engines, gensets, and industrial engines.

ENGINE VALVES

Our engine valves are meticulously crafted using advanced forging techniques, including Extrusion Forging and Upset Forging. They are made from a variety of materials such as Austenitic Steel, Martensitic Steel, and Super Alloys like Nimonic and Inconel. To ensure longevity and performance, our valves undergo Plasma Deposit Hard facing using PTA technology, incorporating materials like Ni60, Stellite, and Triballoy. These processes and materials enhance durability and optimize engine performance for a wide range of applications.

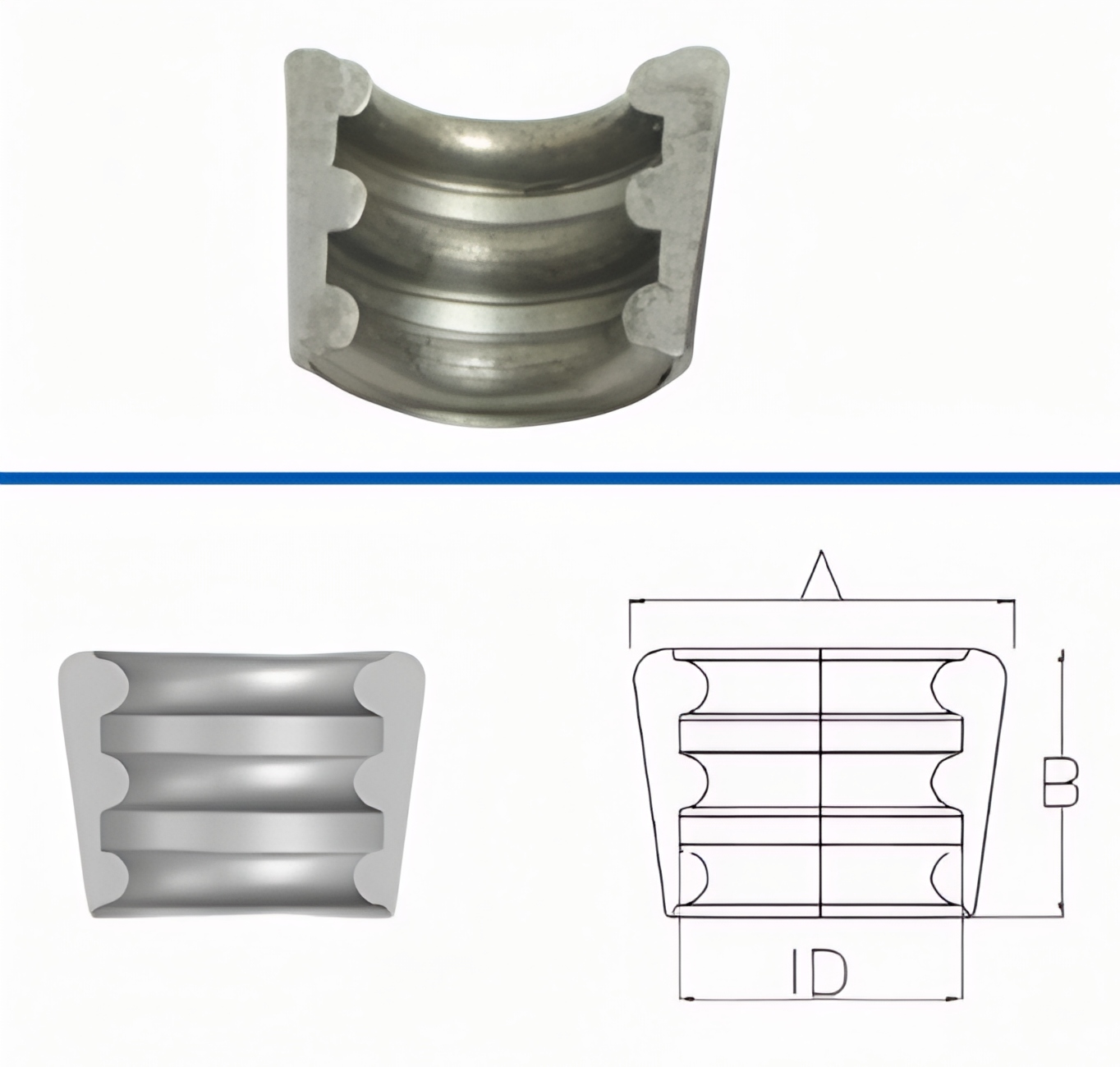

VALVE COLLET PRODUCT FEATURES

Precision Engineering for Enhanced Performance and Reliability.

Our valve collets are meticulously crafted to meet the highest standards of quality and performance. Engineered with precision, these components ensure optimal functionality in various industrial applications.

Name: MK 3

ID: 5, 6, 7, 8, 9 mm

Material: SAE 1010 HARD

Type: Three Bead

Name: LK

ID: 8, 9 mm

Material: SAE 1010 HARD

Type: Three Bead

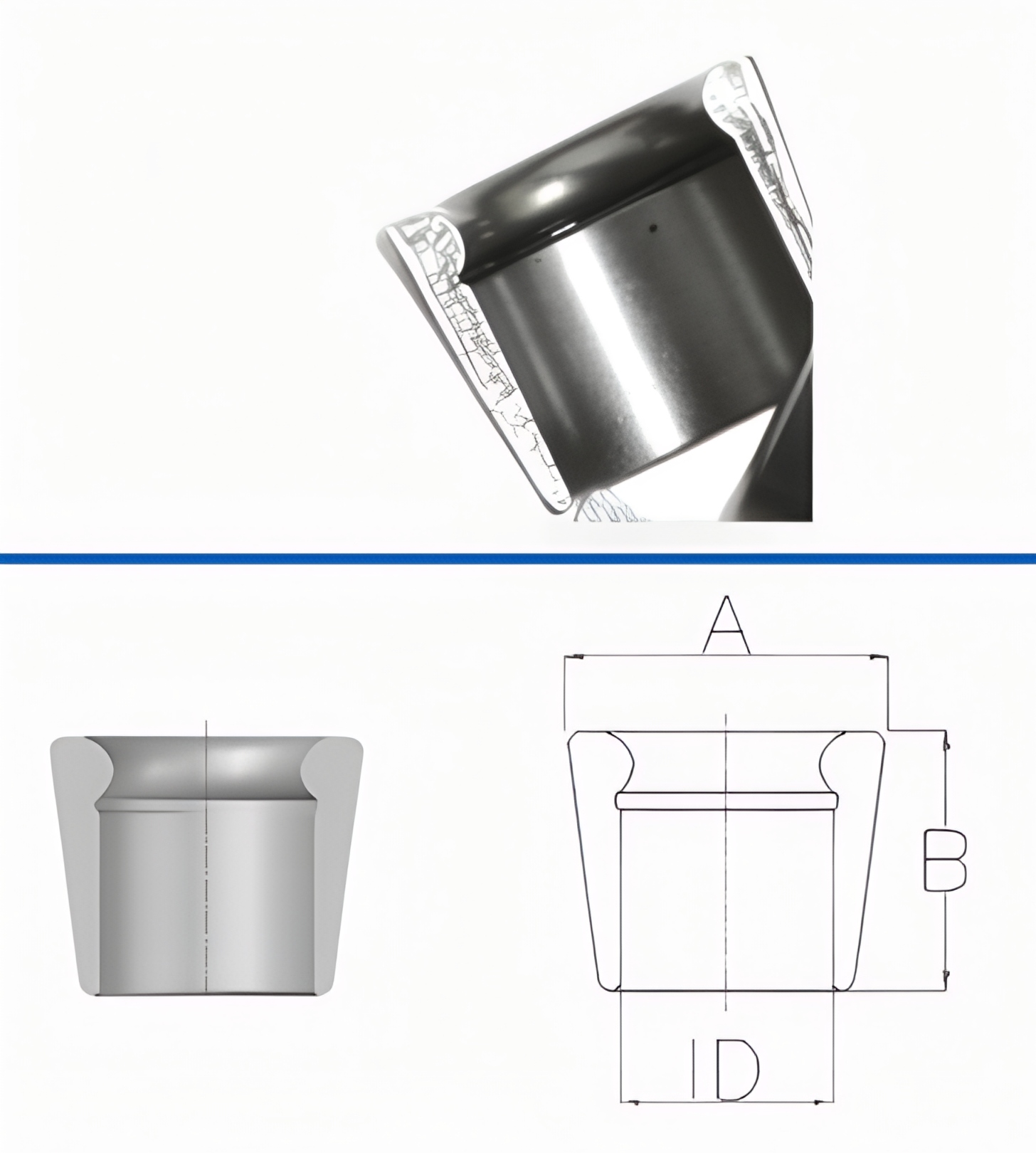

Name: BK

ID: 8, 9, 11, 12.5 mm

Material: SAE 1010 HARD/SOFT

Type: Centre square bead

Name: HH

ID: 4, 5, 5.5 mm

Material: AE 1010 HARD

Type: Small Single Bead

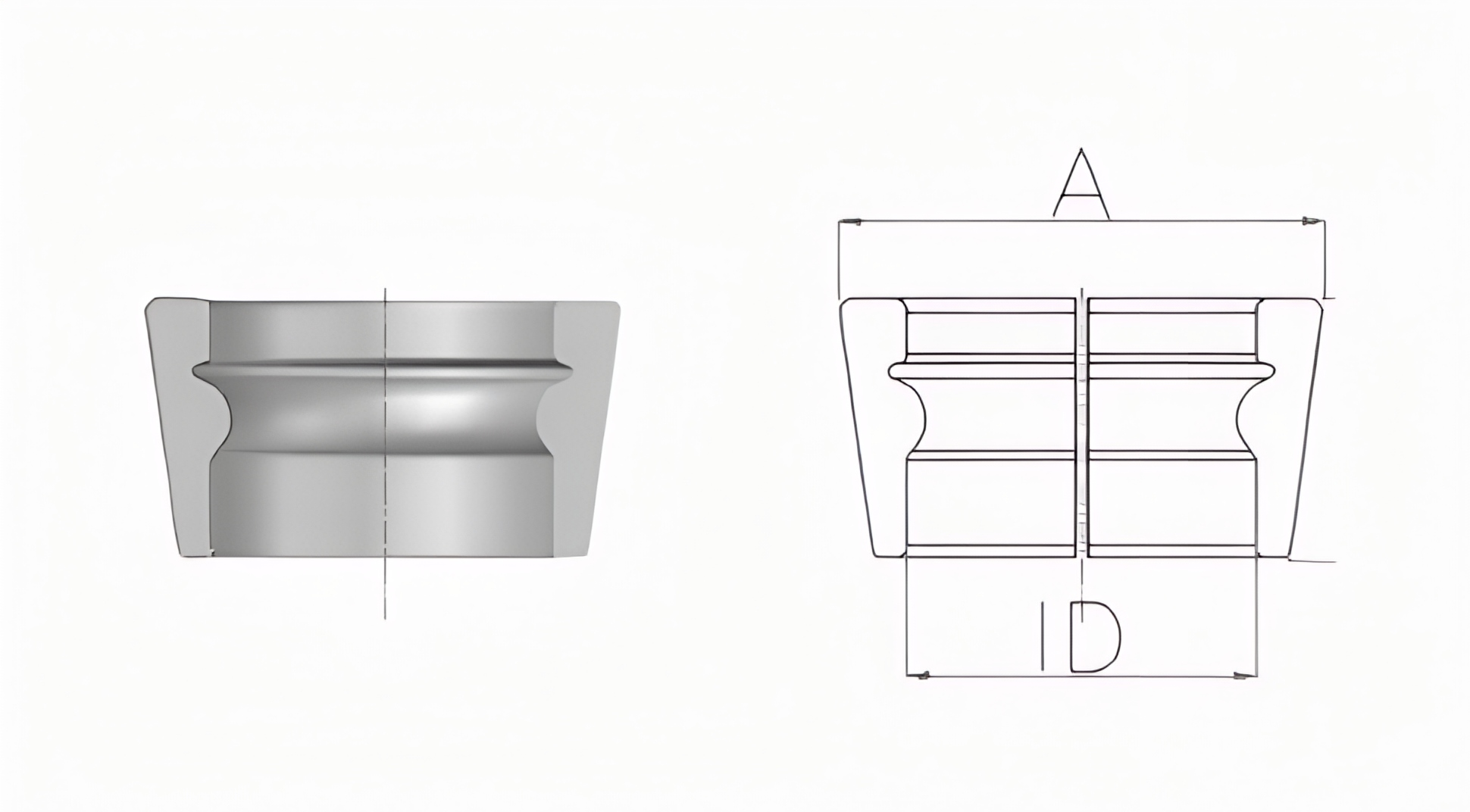

Name: MK

ID: 8, 9 mm

Material: SAE 1010 HARD/ SOFT

Type: Four Bead

Name: KK

ID: 7, 8, 9, 10 mm

Material: SAE 1010 HARD

Type: Single Bead

Name: KB

ID: 5, 6 mm

Material: SAE 1010 HARD/ SOFT

Type: Centre Radiused Bead Small